Products

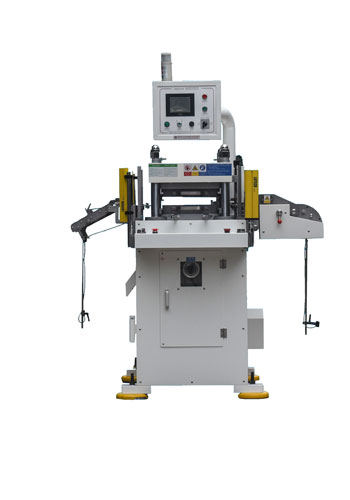

MQG420-12T / MQG420-ZQ

Die

The wooden cut die can be drawn out by unscrew the 4 fixing nuts above. The etch die can be installed with additional pad with the thickness 22. The high parallel accuracy of upper and lower die can avoid the adjustment for half cutting.

Feeding Device

Position materials and provide tension to ensure the material moving in line.

Material Charging Device

Precise material charging device controlled by Servo: accuracy ≤ 0.2%, charged material ≤ 50mm). Discharging and punching work in parallel and 2 sets of synchronous charging rollers will ensure the proper tension for smooth discharging.

Roller uplifting for charging:it is used for production with secondary or more times automatic punching, which is more convenient, efficient and precise. The max speed reaches 150 times / min. The roller above can be unbolted for material feeding and cleaning.

Discharging Components

The machine is equipped with discharging components which can realize simple waste material discharging. The direction, speed and tension for waste material collection can be adjusted. Synchro device is used to make waste material discharging and products rewinding at the same time. The rewinding direction and tension can be adjusted.

Function and Characteristics

· Professional equipment for die cutting industry with the characteristics like precise, reliable, durable and safe.

· Realizing secondary or more times automatic punching and the accuracy reaches ±0.03mm.

· Avoiding adjustment for half cutting;

· Highest punching speed reaching 300spm (MQG200) and 200spm (MQG420);

· Hardware die and its installation standardized, which make installation and adjustment efficient;

· High efficiency and quality equipment for products like black-white film.

· The production capacity of up to 10000 sheets/h;

Technical Parameter of High-speed and Precision Die Cutting Equipment

Item |

MQG420-12T / MQG420-ZQ |

Blank force |

120(kN) |

Cutting stroke |

28(mm) |

Cutting speed |

≤150(time/minites)/≤200(time/minites) |

Die height |

115(mm) |

Adjust the depth of the volume |

±5(mm) |

Fine-tuning mode |

Adjust the depth of the volume automatically |

Stamping method |

Moving inch/single stamp/continuous/project |

Tool size |

Type H (Width 440 X Length 320 (mm))/ Type S(Width 320 X Length 440 (mm)) |

Die type |

Wood plastic die, etch die, hardware die |

Die effective size |

Type H (Width 350 X Length 300 (mm))/ Type S(Width 220 X Length 400 (mm)) |

Material width |

Horizontal type ≤420mm vertical type≤320mm |

Power Motor |

Three-phase asynchronous moto / Customized Servo Motor |

Feeding accuracy |

≤0.2%(Steps greater than or equal to 50 mm) |

Feeding roller |

PU/NBR |

Feeding driver |

Servo motor |

Lubrication |

Automatic lubrication system |

Security |

With three sides of infrared screen and Three-sides PVC protective plate |

Power supply |

Three-phase 380V 15A / Three-phase 380V 30A |

Weight of machine |

2300(kg) |

Air supply |

0.55-0.6Mpa |

Size of machine |

Length: 1700× Width: 1700× Height: 1850mm |

| Optional components: | MQG420-12T / MQG420-ZQ |

Upper waste material collection components |

Optional |

Lower waste material collection components |

Optional |

Components for die rotation and movement |

Optional |

Full cutting charging components (movable) PET |

Optional |

Device for die cutting by tracking specific marks |

Optional |

Absorbed devices for anti-scratch |

Optional |